The Basic Structure and Mechanism

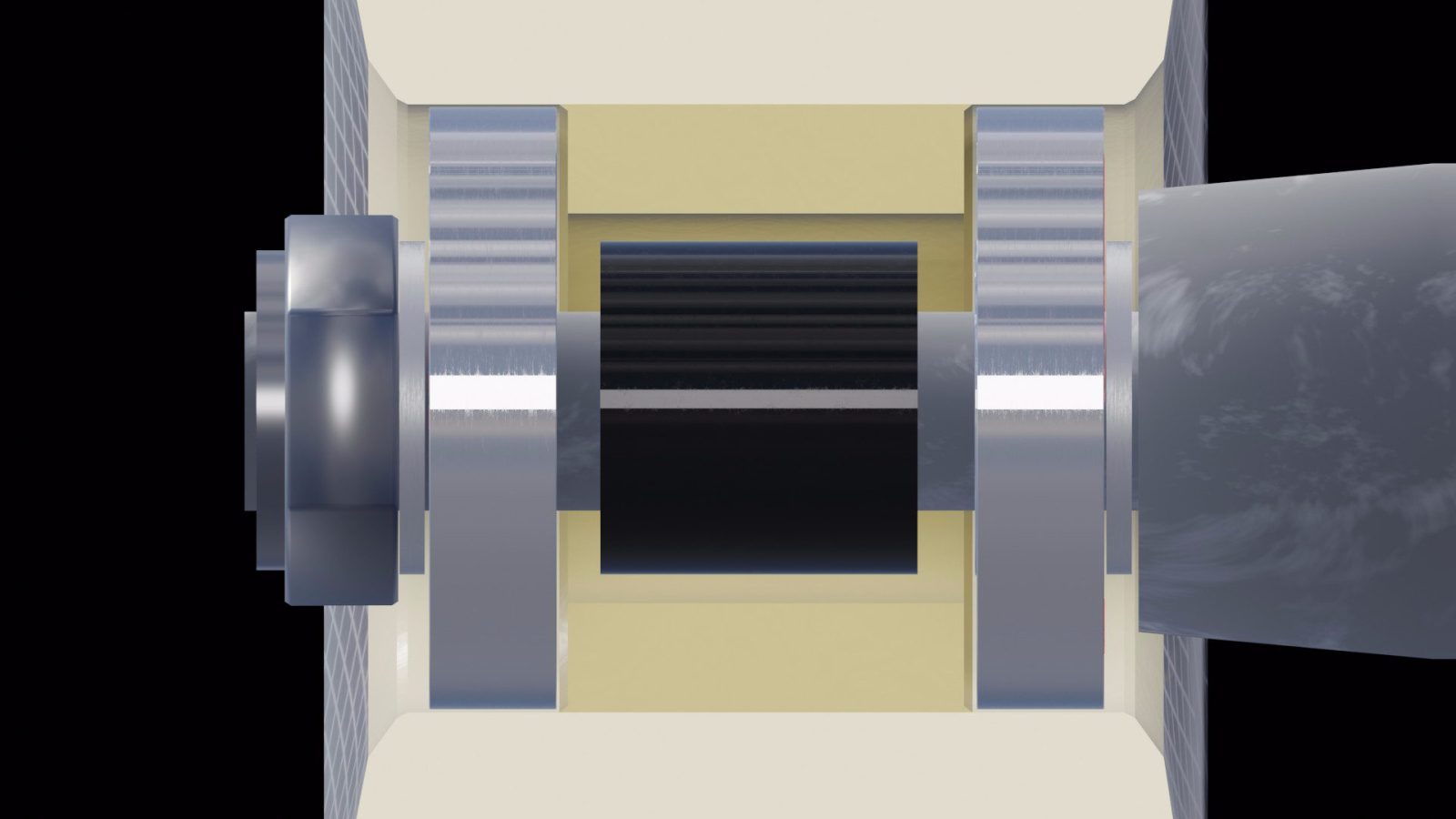

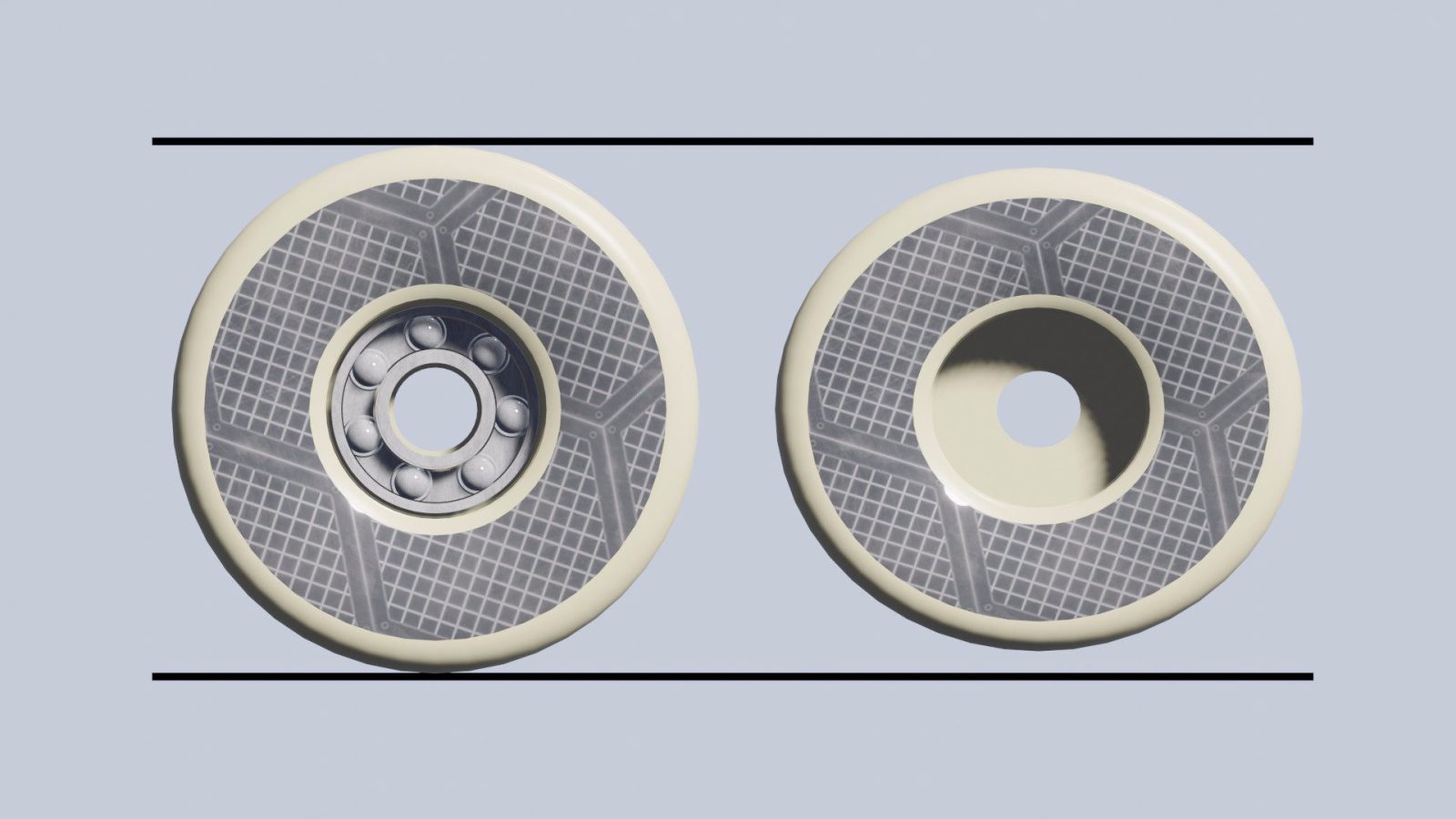

First of all, let's review how a bearing works. A typical bearing consists of a shield, an inner ring, balls, a retainer, and an outer ring. There are two types of lubricants: Oil and Grease. We'll discuss their properties later.

The Myth and Reality of ABEC

One of the most famous concepts about bearings is the ABEC rating, a scale that indicates the manufacturing precision of components. Intuitively, higher precision sounds better—but is it really? Originally, high-ABEC-rated bearings were developed for precision machinery used in fields like medicine, manufacturing, and aviation. For example, dentists use a device called a turbine, which also contains bearings. If simplified, air is fed into the turbine's tip, causing the blades to spin and rotate the drill. Bearings keep the drill shaft perfectly aligned while allowing it to rotate smoothly.

Dental turbines require extremely precise bearings. Their rotational speed is measured in RPM—Revolutions Per Minute—and they spin at an astonishing 300,000 to 500,000 RPM. Assuming these bearings are ABEC-9, and we skate them, exactly how much capacity do we exploit out of them? Let's do some quick maths.

A typical push speed in skateboarding is about 10 km/h, which is roughly 167 meters per minute. If we use a 50 mm wheel, the distance it covers in one rotation is roughly 0.16 meters. Again, the distance we cover in a minute by pushing normally is 167 meters. If you divide it by 0.16 meters, which is the wheel's circumference, you get about 1,060. This means a wheel spins 1,060 times a minute when pushing normally. But ABEC-9 bearing's maximum capability is 500,000 RPM. 1,060 out of 500,000 is only about 0.2%.

Now let's flip the scenario: what if the wheel actually spun at 500,000 RPM? In this case, we need to multiply 0.16m, which is the wheel's circumference, by 500,000. Then, in one minute, the wheel would travel 80 km (500,000 × 0.16 m). If we convert it to speed, it becomes around 4,800 km/h (80 × 60). That's roughly Mach 3.8—the same speed as the top speed of the SR-71 Blackbird.

At that speed, you could finish a full marathon in 32 seconds (42.195 km ÷ 78.5 km/min ≈ 0.54 min), and you could travel from New York to London in about 71 minutes (5,570 km ÷ 4,710 km/h ≈ 1.18 h). That's half the planet in 71 minutes. Do you skate that fast? Probably not.

Another crucial factor that we need to consider is shock and impact. Think back to the turbine. What would happen if you slammed that delicate instrument against the ground? Obviously, it would break. The balls inside the bearing would dent or deform, causing internal wobbling and preventing smooth spinning as before. But "slamming something against the ground" is exactly what we do in skateboarding. Even a single Ollie could deform the internal parts, drastically reducing the precision of high-tolerance bearings. Of course, the bearings still spin; it may become like 100,000 PRM. But in skateboarding, you only need a few thousand RPM anyway, so there's no need for such extreme precision in the first place.

There's another important point about ABEC ratings: ABEC ratings only measure how closely the dimensions of bearing components are to their ideal values. It does not evaluate material quality, surface finish, lubricant properties, or other crucial factors.

Ceramic Balls

Speaking of materials, let's talk about Ceramic balls. Ceramic is the same material used in cups and plates. It doesn't rust, and it's extremely hard so that it won't deform. But ceramics do have drawbacks. Since they're essentially pottery, ceramics can crack when the load is concentrated on a single point. And even if the balls don't rust, the bearing frame is usually still metal and may rust.

Full-ceramic bearings—where even the frame is ceramic—are known to break easily. Skateboard wheels are flexible and compress vertically, pushing against the bearings. If the frame cannot withstand that pressure, it breaks. Understanding the pros and cons of ceramic bearings—and balancing them with your budget—is key to choosing the right bearings for you.

Lubricants

Another factor that influences how smoothly bearings spin is the lubricant. In the first place, why do we even need it? When you stand on your board, friction occurs between the inner components of the bearings. Lubricants create a thin layer between these parts to reduce that friction.

Of the two types of lubricants, oil has lower viscosity, making it easier to accelerate and harder to decelerate. However, because it leaks easily from the bearing, it needs to be replenished regularly.

Grease, on the other hand, has higher viscosity, so it's harder to accelerate, and it slows down more quickly. But many grease bearings are double-shielded, which means they require very little maintenance.

You may have heard people say, "If you remove the oil, the bearings spin better." And yes—during a free spin, when it doesn't receive any load, that can happen. It may be counterintuitive, but lubricants themselves have viscosity or stickiness, which means they can resist rotation to a small extent. But does that mean we should remove lubricants entirely? No, absolutely not. While applying lubricants slows free-spinning, the benefit of reduced friction when bearings are under pressure far outweighs any loss in free-spin performance. In other words, how long a bearing spins when it free-spins has no real meaning.

Shields

Next, let's talk about Shields. The biggest enemy of smooth rotation is dust, and shields prevent it from entering. There was a trend some time ago to remove the shields. The idea was that with the shields off, dirt inside the bearing could escape more easily. But if it can get out easily, it can also get in easily So, I don't see there's any scientific advantage. That said, I love the sound of shieldless bearings. If you have extra bearings, it might be fun to try it.

Spacers

Another important component is the spacer between the bearings. There's been endless debate about whether spacers are truly necessary. Let's start with the argument for using them. Spacers connect the inner rings of the bearings. In tricks like Powerslides, bearings receive sideways forces. With spacers, those forces are distributed between both bearings, reducing the chance of damaging them. But even with spacers, the sideways force somewhat deforms the bearings, which may eventually cause them to break.

And often, the spacer is narrower than the wheel's inner part, so the bearings may not be directly connected. In this case, the spacer practically does nothing but stay there. Personally, I do use spacers as a good-luck charm. But I've never noticed any significant difference in how my board feels with or without them. For these reasons, I don't consider them necessary in practice, in my case, at least.